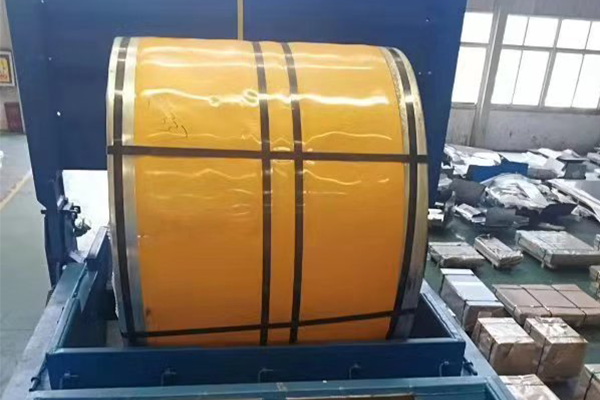

Coil box

Coil box

Compared with ordinary containers, this container has obvious advantages

Compared with ordinary containers, this container has obvious advantages

Roching logistics, as a professional steel logistics service provider, combined with the market and cargo demand, and COSCO Shipping, has customized a special coil steel container for coil steel manufacturers, which has solved the dilemma of high risk, high cargo damage, high cost and difficult loading and unloading in the process of container transportation of extra large coil steel, filled the market gap and is generally favored by coil steel users.

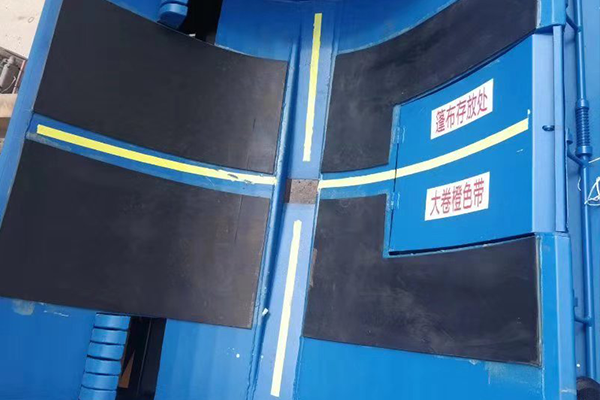

The built-in groove design saves the process of reinforcement and unpacking when packing, and saves more than 70% of the time and cost. Cost savings of more than 40%. Each cargo space has an independent groove design and built-in cushion skin, without any cargo damage, especially for the perfect protection of precision coil steel. |

The specifications and standards of ordinary containers can realize the mutual transformation among automobile transportation, sea transportation and railway, and can also carry out corresponding landing operations. Empty containers can be folded for storage and transportation, which is more flexible and convenient than ordinary containers. |